Eliminate Manual Inventory Pains

Streamline Inventory Audits and Cycle Counts

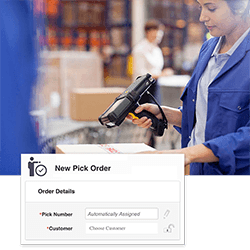

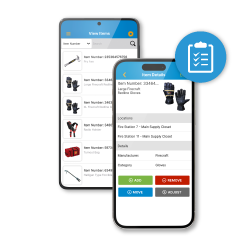

Maintain accurate stock counts, reduce errors, and avoid time-consuming manual entry of items, location bins, pick orders, and inventory receiving – all in one inventory control system. Real-time tracking of inventory level reports allow you to compile and analyze essential data, including transactions by site or warehouse, itemized inventory levels by SKU, or individual customer purchase order history. Wasp empowers business owners and warehouse managers with the types of inventory control software they need so they can keep customers happy from a wide variety of complex supply chains.

Automatic low stock level notifications ensure you keep up with customer demand and never lose out on another sale due to stockouts. Set automatic reorder points down to each bin location as well as preferred vendors for each inventoried item. Exercise true stock control over inventory levels to build your cash flow, all within the cloud-based inventory management software from Wasp.